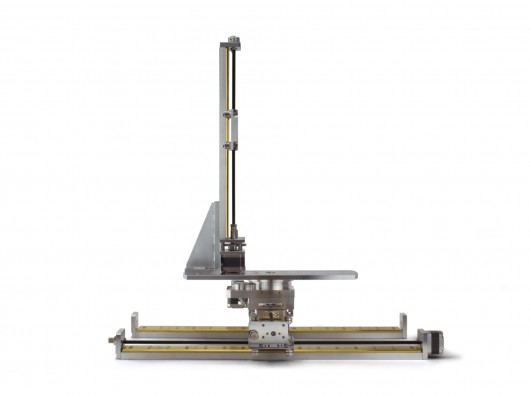

UHV-Compatible 4-Axis Mechanism

Posted on Tuesday 22nd March 2022 at 9:45

Working closely with a customer, AML have designed and manufactured this custom 4-axis mechanism. This unique mechanism has been specifically configured for use in the customer's UHV environment, for their application.

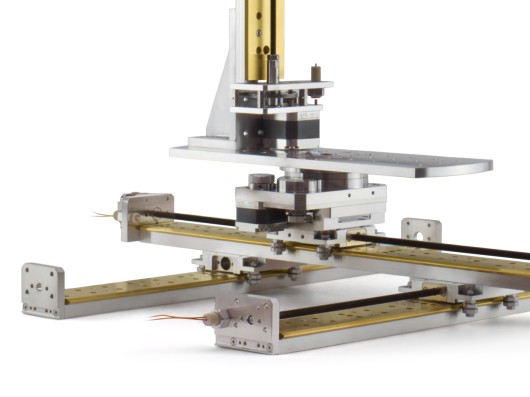

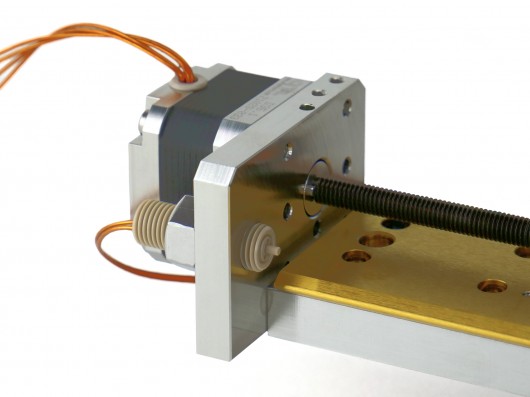

The mechanism is driven by our UHV compatible stepper motors and features LTVL-400 and LTVL-250 linear stages. An RSX3K6 rotation stage provides the rotational axis. Due to the size of the mechanism, an additional LTV-400 is used to support the X-axis.

- Vacuum: 1E-7 mBar

- Temperature: −20 °C → +80 °C

- Load: 20 kg

- Linear stage resolution per step (X,Y): 5 μm

- Linear stage resolution per step (Z): 1 μm

- Rotation stage full step resolution: 0.01°

The X, Y and Rz axis are all driven with D35.1 UHV stepper motors. With 400 mm of travel on both the X and Y axis, this mechanism provides the user with large amounts of flexibility and control of each axis. A D42.1 drives the Z stage, achieving a resolution of 1 μm per step.

Limit switches were required by the customer for homing each axis, Two VLS1 UHV compatible limit switches were provided on each linear stage, enabling a repeatable zero-position to be established.

To comply with the customer's requirements, the mechanism was constructed and assembled using only UHV-compatible methods and materials. The mechanism was built and extensively tested in our ISO class 7 cleanroom, ensuring its quality, performance and UHV-compatibility. At each stage of construction, testing was carried out. Read more about the testing performed on our UHV Stepper Motors here: /news/how-an-aml-uhv-compatible-stepper-motor-is-made/

Listed below is the finalised specification of the mechanism:

| Axis | X | Y | Rz | Z |

|---|---|---|---|---|

| Motor type | D35.1 | D35.1 | D35.1 | D42.1 |

| Stacking order | 4 | 3 | 2 | 1 |

| Lubrication | Nyetorr® 6300 | Nyetorr® 6300 | Nyetorr® 6300 | Nyetorr® 6300 |

| Guide type | V-groove bearing | V-groove bearing | Crossed roller | V-groove bearing |

| Load (kg) | 20 | |||

| Travel (deg/mm) | ±200 mm | ±200 mm | ±180° | ±125 mm |

| Resolution (per step) | 5 μm | 5 μm | 0.01° | 1 μm |

NyeTorr® ultra-low outgassing grease was used on the motor bearings, leadscrews, worms and gears. This helps ensure the operational longevity of the mechanism.

If you would like to discuss your in-vacuum motion system requirements, please do not hesitate to contact our dedicated team by emailing sales@arunmicro.com.