Support

Access help for your product.

Our sales, engineering, and technical support teams are dedicated to delivering exceptional customer service. We provide technical support for every product in our lineup.

Our sales, engineering, and technical support teams are dedicated to delivering exceptional customer service. We provide technical support for every product in our lineup.

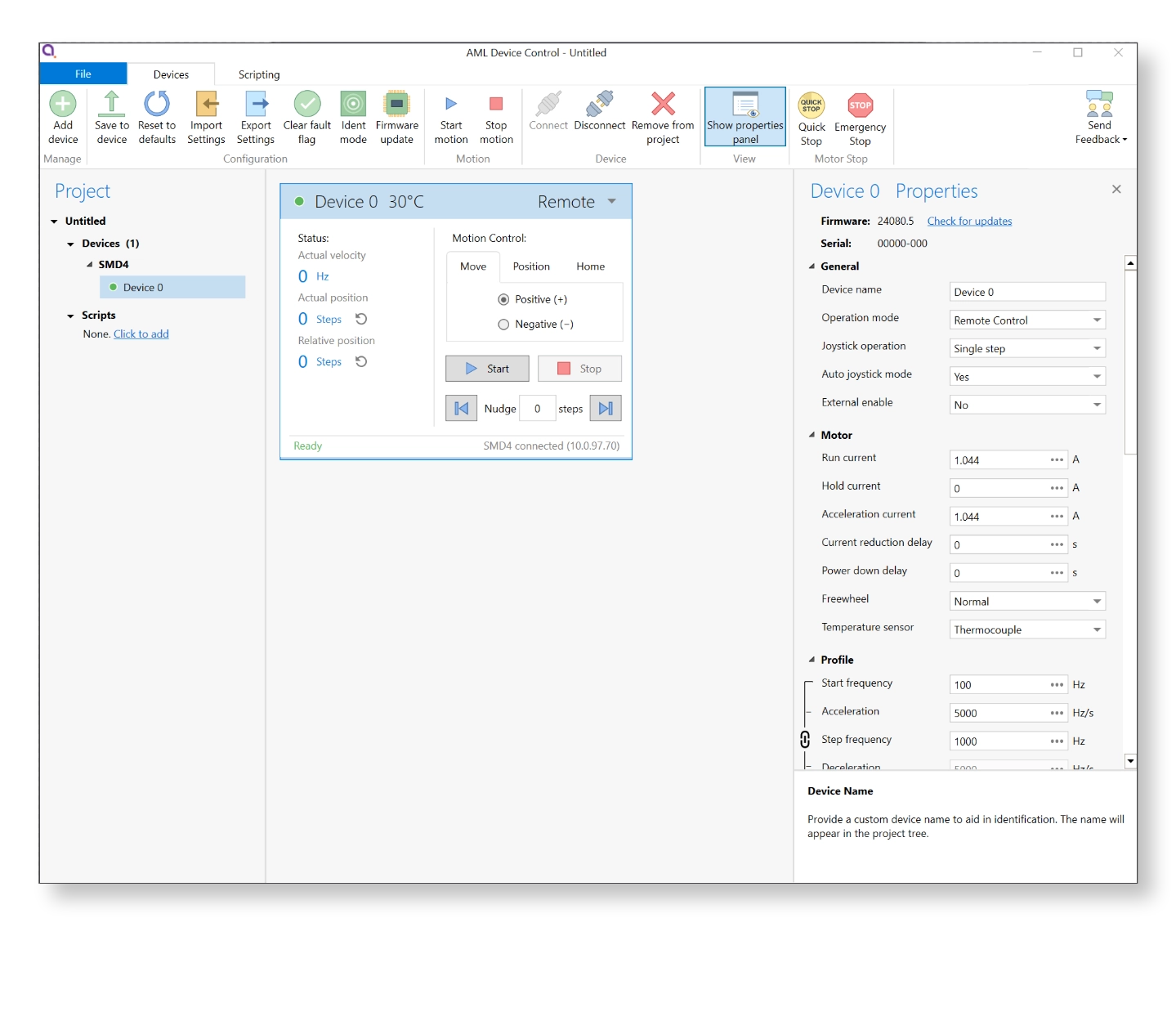

Software developed to make interfacing with our products easy.

Download

Check manual for troubleshooting advice, ensuring that the fault is definitely with the AML device.

Contact support stating the model number, serial number and a brief description of the fault.

If necessary, an RMA number will be issued. Ship the instrument back to us, following the instructions we provide.

We diagnose and repair the instrument if possible, soak-test it and ship it back to you, usually in 3-4 weeks.

Instruments models PGC1, PGC2, PGC2D, NGC2, NGC2D, NGC3 & SMD210 that are less than 20 years old are eligible for repairs.

Serial numbers starting with a letter correspond to the year of manufacture:

Nxxx yyy = 2003

Oxxx yyy = 2004

Pxxx yyy = 2005

Eight-digit serial numbers start with the year of manufacture:

13xxx-xxx = 2013

14xxx-xxx = 2014 and so on.

The standard repair charge is £352.00, with 98% of repairs being completed within this standard charge. Return carriage is extra.

AML will provide an estimate or advise that the instrument is beyond economic repair. If our repair estimate is greater than the standard charge, we will require a new or amended order, or will issue a new prepayment invoice. AML reserve the right to declare any instrument beyond economic repair at any time. AML will not normally charge for instruments that cannot be repaired. If an instrument is returned to the customer without charging for a repair, then AML reserves the right to remove sub-assemblies that have been fitted.

A calibration, safety, and soak test will be completed, and the charge may be reduced.

Most repairs will be completed within 3 - 4 working weeks, however, depending on component and resource availability, repairs can sometimes take up to 8 weeks. Delay in providing an order, any requested information or invoice payment will extend this.

AML reserve the right to dispose of instruments returned without a covering order, a return authorisation (RMA), disposal instructions or with an unpaid invoice.

Generally, no service report is provided unless an application problem or misuse is detected, or if a service report is requested, for which AML will charge.

To fully test the instrument, settings may be altered or reset to default. It's advisable to record settings and re-set them as required after the instrument is returned.

No, it is very risky. BA Gauges are very fragile. These and the leads can be adequately tested with an ohmmeter. BA gauges with leaky feedthroughs or distorted grids should be scrapped. Gauges should not be returned for replacement of filaments, as this is a simple procedure and instructions are provided with replacement filament kits. Pirani gauges are inexpensive and do not justify repair.