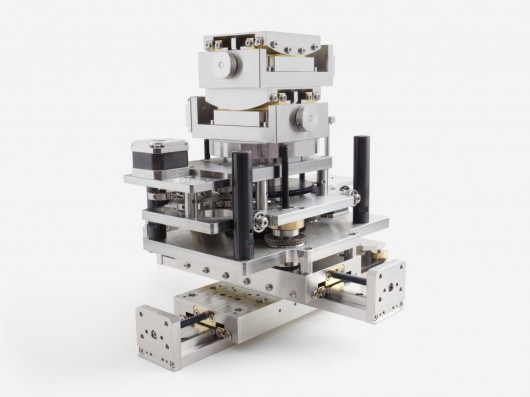

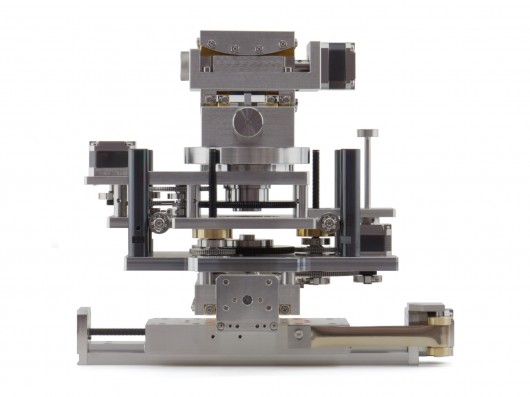

UHV-Compatible Custom 6-Axis Manipulator

Posted on Wednesday 10th November 2021 at 12:16

As a design and manufacturing specialists of in-vacuum motion systems, AML can accommodate your application-specific requirements. We were contacted by a customer requiring a UHV-compatible 6-axis manipulator for a high-energy synchrotron radiation source application. Working closely with the customer, we designed a custom manipulator stage using a combination of our standard LTX linear translators and custom designed linear, rotation and goniometer stages. The customer provided the travel and load parameters as well as some other key design requirements.

- Vacuum: 1E−7 mBar

- Temperature: −65°C → +175°C

- Load: 5 kg

- Linear stage full step resolution: 5 μm

- Rotation and goniometer stage full step resolution: 0.01°

A 6-axis manipulator was designed and approved by the customer, ensuring that it was capable of meeting the customer’s requirements. The stage includes two LTXL-85 rigid linear translator stages, a custom-design Z-axis linear translator stage, a custom design rotation stage and two custom goniometer (swing) stages.

Six of our D35.1 UHV-compatible stepper motors were used to drive the 6 axes via anti-backlash gearing systems.

The mechanism was constructed using only UHV-compatible materials, and assembled using UHV-compatible methods, in a dedicated ISO class 7 cleanroom at our factory in the United Kingdom.

An array of SMD3 Stepper Motor Drives were used to extensively test each axis of the manipulator stage, to ensure that it operates to AML’s high standard. The final specification is as follows:

| Axis | X | Y | Z | Rz | Rx | Ry |

|---|---|---|---|---|---|---|

| Motor type | D35.1 | D35.1 | D35.1 | D35.1 | D35.1 | D35.1 |

| Stacking order | 6 | 5 | 4 | 3 | 2 | 1 |

| Lubrication | Nyetorr® | Nyetorr® | Nyetorr® | Nyetorr® | Nyetorr® | Nyetorr® |

| Guide type | Crossed roller | Crossed roller | Crossed roller | Crossed roller | Crossed roller | |

| Load (g) | 5000 | |||||

| Travel (deg/mm) | 85 mm | 85 mm | 50 mm | ±180° | ±15° | ±15° |

| Resolution (per step) | 5 μm | 5 μm | 1 μm | 0.01° | 0.005° | 0.005° |

Nyetorr® ultra-low outgassing grease was used on the motor bearings, leadscrews, worms and gears to increase the life of the mechanism.

Read more about vacuum mechanisms from AML here, or to discuss your in-vacuum motion enquiry, please do not hesitate to contact our dedicated team by emailing info@arunmicro.com.